Roof Replacement in Seattle, WA 98133

Call our Roof Replacement line at 888-479-8303 for a prompt response to roof leaks and other roofing issues.

Our responsive team will dispatch a service technician to your site rapidly, depending upon the severity of the roof damage, to quickly examine your residential or commercial roof and make necessary repairs on the spot.

When it includes putting the best touches on a house our roofing solutions can quickly include curb interest any house. We can help you make a expert roofing strategy to guarantee that your home will be the very best it can be. The possibilities are unlimited when you call our Roofing contractor Providers.

Continue Reading ...

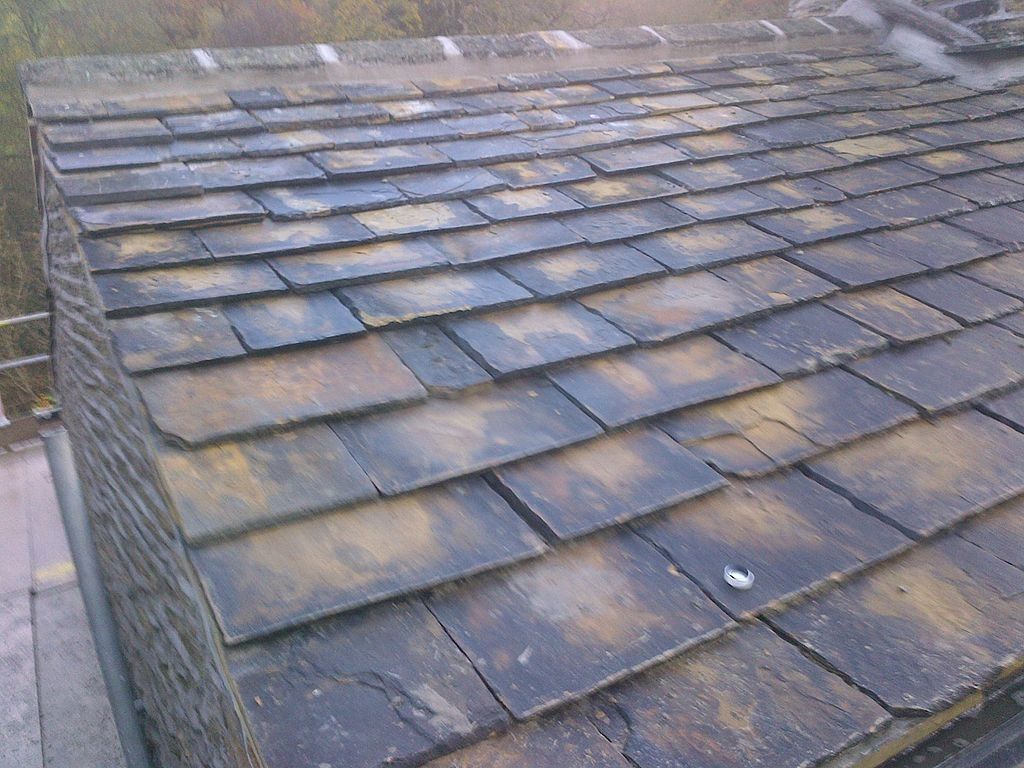

Timeless Roof

With all the roof design and styles that you can choose in the market today, you probably need a little assistance to press you to the right direction. Correct preparation and substantial time ought to be allocated in selecting the ideal roofing design that would best match your home. roofs considerably contribute to the look you want your house to illustrate.

In considering classic roof designs, you'll maybe discover the variety almost unlimited. Timeless roofing often requires a substantial quantity of workmanship and competence. That is why aside from selecting premium grade materials, it is equally important to hire just the best roof professionals in your location.

Typically, the use recycled roof materials are perfectly proper to assist you in attaining the classic roof design to want to pull off. It is likewise advisable to use the light-weight, synthetic products if you like the conventional, traditional roof design.

standard roof materials frequently utilized frequently can not withstand high winds and other serious weather elements as effectively as artificial materials. There are steel tiles which are created to appear like classic roof tile however with the benefit of simpler installation and considerably more affordable too. Synthetic roof products are readily available in various styles and textures that you can select from to achieve the look you seek for your roofing system. The synthetic traditional roof will not only give you the security and coverage against harsh climate condition, you can with confidence expect it to last longer than the basic cedar or slate roofs.

There are numerous more recent slates and imitation shakes that are in fact filled with rubber substances, making it capable to better prevent the hazardous UV rays, and more resilient and fire resistant. Artificial materials are notably much easier to install using air pressured nail weapons.

first deciding the style of roofing to want to adjust, be sure to assess the advantages of every option. Decide which design that will best boost the charm of your home, and would still offer the toughness that you need.

In thinking about timeless roof designs, you'll maybe find the variety nearly endless. Often, the use recycled roof materials are completely suitable to assist you in achieving the classic roof style to desire to pull off. It is likewise suggested to utilize the lightweight, artificial products if you like the traditional, timeless roof design.

The synthetic traditional roof will not just give you the security and protection versus extreme weather condition conditions, you can with confidence expect it to last longer than the standard cedar or slate roofing systems.

Roofing Leak Repairs near Seattle, WA 98133

Our expert Leak Repair Roofers provide Expert Roofing Services. If you have any questions or concerns about our service area, please give us a call today. We are competitively priced in the city from other roofing companies because we are confident that you will be thrilled with how your roofing project will turn out. Again, call today to schedule a consultation for your roofing needs.

Concrete Roof

roofing is a common option of homeowners these days as it provides a durable structure for your roofing because of the structure of the product. One may require to think about the cost or expense of using concrete roofing. It is built to last, however you might have to pay the rate.

roofing is carefully related to one kind of roofing products which is concrete tiles. This is due to the fact that concrete roofing is a structure of cement-based resources like concrete, fiber cement, minerals, and asphalt. Slate and structure shingles can likewise be other examples of concrete roofing. Concrete product is shaped and molded with high pressure to produce a hardwearing and thick tile. It is particular to last sixty years and even more after installation. A lot of homes in Europe are developed on concrete roof. And if you may not even know it, a lot of those homes have concrete roofing systems that are more than a hundred years old. That is why concrete roofing is appropriately called as the roofing system of a lifetime.

If you wish to invest in your own home without the concern of routine upkeep, concrete roofing works best for you. Aside from being a long-lasting material, it adds to the beauty and artistic appearance on your house.

You got it wrong when you believed that concrete roofing is all but the gray looking cement that we typically see. For many years, innovative improvements were made to redesign and recreate more recent and more elegant concrete roofing tiles. There used to be the standard Spanish design ceramic roofing which is available in a mission S-tile type. More choices nowadays range from Mediterranean style to shake shingles that might either can be found in villa or flat tile type, and the classic cast stone & slate which appears as a flat tile type. Mission S-tile is called as such due to the fact that it merely looks like the letter "S" while the rental property tiles look like a double letter "S". On the other hand, flat tiles are the common flat emerged materials that are made to appear like wood slates or shakes.

Concrete roof is a common option of homeowners these days as it provides a well-built foundation for your roofing because of the structure of the product. Concrete roof is carefully associated with one type of roofing products which is concrete tiles. When you believed that concrete roofing is all but the gray looking cement that we frequently see, you got it wrong. Over the years, innovative improvements were made to upgrade and recreate more recent and more elegant concrete roofing tiles.

Continue Reading ...

Show Less

Show Less

We at Stuart Roofer Servicess aim to produce the roof of your dreams! Call us today and set up a consultation with our specialist roofers. You won’t be dissatisfied. Call today for Roofing Services!

We can provide Emergency Roof Repair for all areas in Seattle including: King County, Shoreline, Bitter Lake, Richmond Highlands and in Area Codes 206,425