Roof Leak Repairs in Jefferson, GA 30549

Call our Roofing Leak Repairs line at 888-479-8303 for a prompt response to roof leaks and other roofing issues.

Our responsive team will dispatch a roofing contractor to your site within hours, depending on the severity of the roof damage, to quickly assess your residential or commercial roof and make necessary repairs on the spot.

When it includes putting the best touches on a house our roofing services can quickly include curb appeal to any house. We can assist you make a expert roofing plan to ensure that your home will be the very best it can be. The possibilities are endless when you call our Roofing professional Providers.

Continue Reading ...

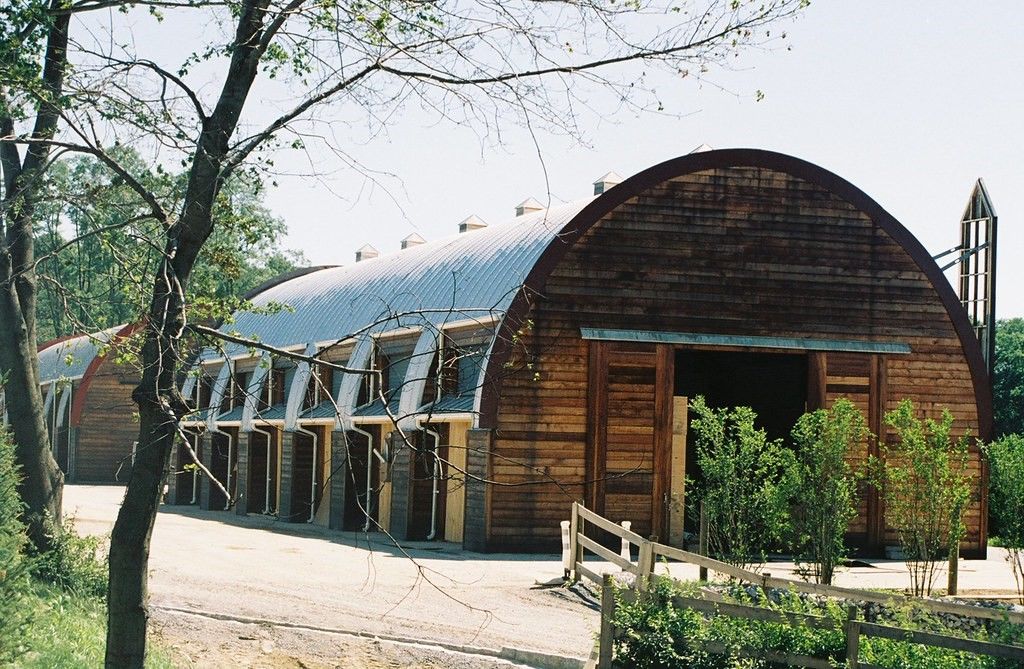

Aluminum Roof

understand that Americans muddle through an average of 10, 000 thunderstorms, 2, 500 floods, 1, 000 tornadoes and 6 deadly typhoons every year? This is quite a lot to compete with! Just think about the struggle your roofing system needs to put up with every single day. The unrelenting heat of the sun and the heavy rainstorms contribute a lot to the wear and tear of your roofing system. This is the reason that it's extremely crucial to purchase durable roof products. The attack of severe weather conditions calls us to upgrade our roof in rush. You can simply picture the dollars you can most likely save and the lives you can secure by spending for a tough roof to protect your life and valuables.

roofing is known to be one of the least pricey kinds of roof material readily available in the market today. More frequently utilized on business structures, aluminum roofing is also anticipated to be popular amongst homeowners considering that it is also known to be an energy saver. Aluminum has been understood to reflect heat. Some aluminum roofing system materials actually have heat conserving chips, meaning you can in fact cut down a substantial quantity on your energy bills!

leakages and roofing failures can wreck havoc on homes and can cost you an impossible quantity of money if your home is not guaranteed. Aluminum roofing naturally does not rust and does not need the expensive paint systems to prevent rusting.

Your home insurance would most likely go down when you have aluminum roof considering that it's essentially fire-resistant. Typically steel or aluminum roofing systems comes with a 50-year guarantee. That is why aluminum roof is a clever choice for your organization or house.

Aluminum roof is known to be one of the least costly types of roofing material available in the market today. More frequently utilized on industrial structures, aluminum roof is also anticipated to be popular amongst house owners since it is likewise understood to be an energy saver. Your home insurance coverage would probably go down when you have aluminum roof because it's essentially fireproof. That is why aluminum roof is a smart choice for your company or house.

Roofing Leak Repairs near Jefferson, GA

Our expert Leak Repair Roofers provide Roof Leak Repairs. If you have any questions or concerns about our service area, please give us a call today. We are competitively priced in the city from other roofing contractors because we are confident that you will be thrilled with how your roofing project will turn out. Again, call today to schedule a quote for your roofing job.

Leaking Roof Repairs in Jackson County

Ensuring you have Appropriate Roofing System Ventilation

Taking care of your roofing system

looked after roof lasts a lot longer than a roof that is delegated it's own devices. By finding problems early on you can save yourself a lot of heartache and extra expense from big issues Your roof is accountable for taking the damage from everything that the components can throw at it consisting of wind, snow, rain and sun but it is also assaulted by leaves, insects and other natural predators. Inefficient roof can imply that any of these elements discover their method into your attic and ultimately your house and it is important you do what you can to prevent this from happening.

Small issues lead to big issues.

damages and leakages is through a regular, expert upkeep check performed by an experience roofing contractor in your place. These checks are not as expensive as you may believe and problems that area spotted early can be repaired before they worsen. One such issue that you need to routinely have examined is that you have appropriate roofing system ventilation which it is working effectively.

What is proper roofing system ventilation?

a consumption or an exhaust, correct roof ventilation need to comprise of both of these crucial elements in order to develop effect air flow in and out of your home. Not just will this secure your roofing system and your home however it will also help manage the amount of time you utilize your a/c, hence bringing down the cost of your energy expenses. There are a variety of ways that correct roofing system ventilation can be accomplished and each have their benefits and drawbacks. The best option for your roofing system will depend on the shapes and size of the roofing system, and the design of surrounding trees, wires and other things.

Producing appropriate roofing ventilation

create correct roof ventilation that adequately turns air in and out of your house it is important to get the level of consumption and expulsion just right. This must be done by a qualified professional who can exercise the figures needed and advise you of the very best course of action. Without professional guidance you may find that you have an inaccurate flow of air, which can not only imply an extremely hot house in summertime however it can likewise indicate a wetness build up in your loft and eventually deformed, split, broken or typically harmed roofs.

Reasons for moisture buildup in the attic

It isn't always the fault of the weather condition either. Cleaning machines, dryers and other home appliances in addition to the residents of the house all create their own wetness and without correct roofing system ventilation this moisture will develop on the within your roofing. With a proper roofing system ventilation system a negative air pressure is developed that draws the warm air out of the loft changing it with cool fresh air from outdoors avoiding various types of damage connected with bad ventilation systems.

A well cared for roof lasts much longer than a roofing that is left to it's own devices. Correct roofing ventilation doesn't consist of either an exhaust or a consumption, correct roof ventilation should make up of both of these essential elements in order to develop impact air blood circulation in and out of your house. The finest choice for your roofing will depend on the size and shape of the roof, and the layout of surrounding trees, wires and other items.

Washing machines, dryers and other family home appliances as well as the residents of the home all create their own moisture and without appropriate roof ventilation this wetness will develop up on the inside of your roof.

Show Less

We at Stuart Roofer Services aim to produce the roof of your dreams! Call us today and set up a consultation with our specialist roofers. You won’t be dissatisfied. Call today for Roofing Services in Jefferson!

We can provide Roof Leak Repairs for all areas in Jefferson including: Jackson County, Arcade, and in Area Codes 706