Roof Leak Repairs in Corning, OH 43730

Call our Roofing Leak Repairs line at 888-479-8303 for a prompt response to roof leaks and other roofing issues.

Our responsive team will dispatch a roofing contractor to your site within hours, depending on the severity of the roof damage, to quickly assess your residential or commercial roof and make necessary repairs on the spot.

When it involves putting the best touches on a house our roofing solutions can easily add curb appeal to any house. We can aid you make a professional roofing strategy to make sure that your home will be the very best it can be. The possibilities are limitless when you call our Roofer Providers.

Continue Reading ...

regional or national trade companies.

Numerous resources are offered to find a qualified roofing contractor; referrals, city government licensing firms, and web sites that offer specialists for hire, or a list of specialists who are certified and bonded.

A licensed roof specialist can be called to prevent more damage to the roofing system, or individual injury to the property owner triggered by trying to inspect it his or her self. A roofing examination must be carried out each year; continuous weathering by sun, heat, rain, snow, cold, wind, and hail can trigger roof product to break down. An accredited roof contractor will know what to look for.

Ask potential roof professionals concerns such as whether or not they are licensed and bonded.

Roofing Leak Repairs near Corning, OH

Our expert Leak Repair Roofers provide Roof Leak Repairs. If you have any questions or concerns about our service area, please give us a call today. We are competitively priced in the area from other roofing contractors because we are confident that you will be thrilled with how your roofing project will turn out. Again, call today to schedule a quote for your roofing needs.

Leaking Roof Repairs in Perry County

Guaranteeing you have Correct Roofing System Ventilation

Taking care of your roof

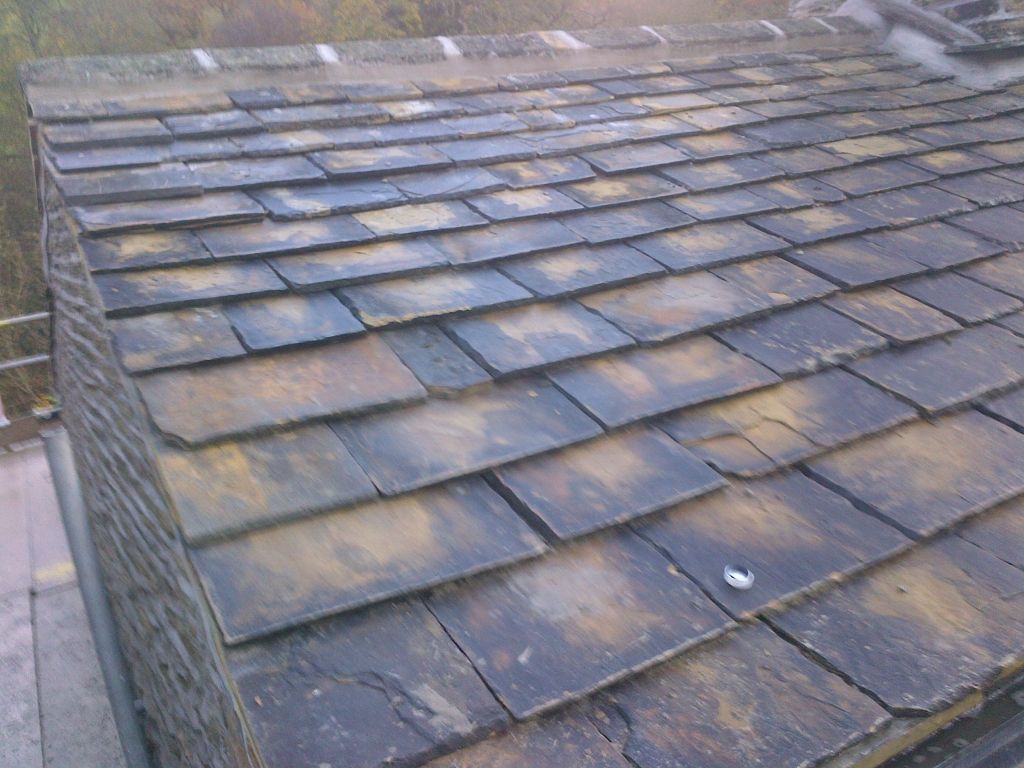

A well cared for roof lasts much longer than a roof that is left to it's own devices. Your roof is responsible for taking the damage from everything that the components can throw at it consisting of wind, sun, snow and rain but it is also attacked by leaves, insects and other natural predators.

Small problems lead to big problems.

The roofing itself is one element of the home that is routinely neglected by house owners up until there is an obvious leakage or damage. One such issue that you should regularly have inspected is that you have proper roofing system ventilation and that it is working successfully.

What is proper roofing ventilation?

Appropriate roofing system ventilation doesn't consist of either an intake or an exhaust, proper roofing system ventilation should make up of both of these crucial elements in order to create impact air circulation in and out of your home. The best choice for your roofing will depend on the size and shape of the roof, and the design of surrounding trees, wires and other things.

Developing proper roofing system ventilation

produce correct roofing system ventilation that properly rotates air in and out of your home it is essential to get the level of consumption and expulsion ideal. This ought to be done by a qualified expert who can exercise the figures needed and advise you of the very best course of action. Without specialist recommendations you may discover that you have an incorrect flow of air, which can not only mean an extremely hot home in summer season however it can likewise mean a wetness develop in your loft and ultimately warped, split, split or normally harmed roofing systems.

Causes of wetness buildup in the attic

It isn't constantly the fault of the weather either. Washing devices, clothes dryers and other household appliances along with the occupants of the house all create their own wetness and without proper roofing system ventilation this wetness will build up on the within your roofing system. With a proper roof ventilation system an unfavorable air pressure is developed that draws the warm air out of the loft replacing it with cool fresh air from outdoors avoiding numerous kinds of damage associated with bad ventilation systems.

A well cared for roof lasts much longer than a roof that is left to it's own gadgets. Appropriate roof ventilation does not consist of either an exhaust or a consumption, appropriate roofing system ventilation need to comprise of both of these essential components in order to produce effect air circulation in and out of your home. The best option for your roofing system will depend on the size and shape of the roofing system, and the layout of surrounding trees, wires and other things.

Washing devices, clothes dryers and other family devices as well as the occupants of the house all create their own wetness and without appropriate roofing system ventilation this moisture will construct up on the within of your roof.

Show Less

We at Stuart Roofer Services aim to produce the roof of your dreams! Call us today and set up a consultation with our specialist roofers. You won’t be dissatisfied. Call today for Roofing Services in Corning!

We can provide Roof Leak Repairs for all areas in Corning including: Perry County, Hemlock, Rendville, and in Area Codes 740