Roof Leak Repairs in Cleveland, OH 44128

Call our Roofing Leak Repairs line at 888-479-8303 for a prompt response to roof leaks and other roofing issues.

Our responsive team will dispatch a roofing contractor to your site within hours, depending on the severity of the roof damage, to quickly assess your residential or commercial roof and make necessary repairs on the spot.

When it includes putting the best touches on a house our roofing solutions can easily include curb appeal to any home. We can help you make a expert roofing strategy to make sure that your home will be the best it can be. The possibilities are limitless when you call our Roofer Services.

Continue Reading ...

Algae Resistant Roof Shingles

Numerous house owners are strained with unwanted house visitors every year. It's not the kind of visitors that you're considering, however, as this visitor doesn't enter the home. It welcomes itself to rest on your roofing system and triggers unattractive staining. It's algae and it impacts a great deal of house owners, especially those who reside in locations of high humidity. Algae, however, doesn't victimize those who do not live in highly damp climates. It will connect to any roofing system and can be carried through wind, squirrels, birds, and so on.

The Copper Concept

The principle behind algae resistant roof shingles is actually quite simple. The copper isn't visible, however it's presence is definitely felt by unsuspecting algae as it is not able to make it through on your roof's surface area. The copper or zinc present in algae resistant shingles are activated even more by rain, which disperses the algae fighting parts even further along the roof's surface.

Producers Of Algae Resistant Roof Shingles

Many of today's leading shingle manufacturers provide algae resistant roofing shingles, which can be set up by a local roof contractor. In lots of cases, service warranties are even offered to cover algae resistant shingles.

Finding A Professional

An expert roofing contractor in your location will be able to order, and set up, your choice of algae resistant roofing system shingles. Understanding that your roofing system is protected, from undesirable algae, will offer you a higher peace of mind and permit your home to remain fungus-free and lovely.

The concept behind algae resistant roofing system shingles is in fact quite simple. The copper isn't visible, but it's existence is definitely felt by unwary algae as it is unable to endure on your roof's surface area. The copper or zinc present in algae resistant shingles are activated even more by rain, which disperses the algae fighting parts even further along the roof's surface area. Numerous of today's leading shingle producers use algae resistant roof shingles, which can be installed by a local roof professional. An expert roofing contractor in your location will be able to order, and set up, your choice of algae resistant roofing shingles.

Roofing Leak Repairs near Cleveland, OH

Our expert Leak Repair Roofers provide Roof Leak Repairs. If you have any questions or concerns about our service area, please give us a call today. We are competitively priced in the city from other roofing companies because we are confident that you will be thrilled with how your roofing project will turn out. Again, call today to schedule a consultation for your roofing needs.

Leaking Roof Repairs in Cuyahoga County

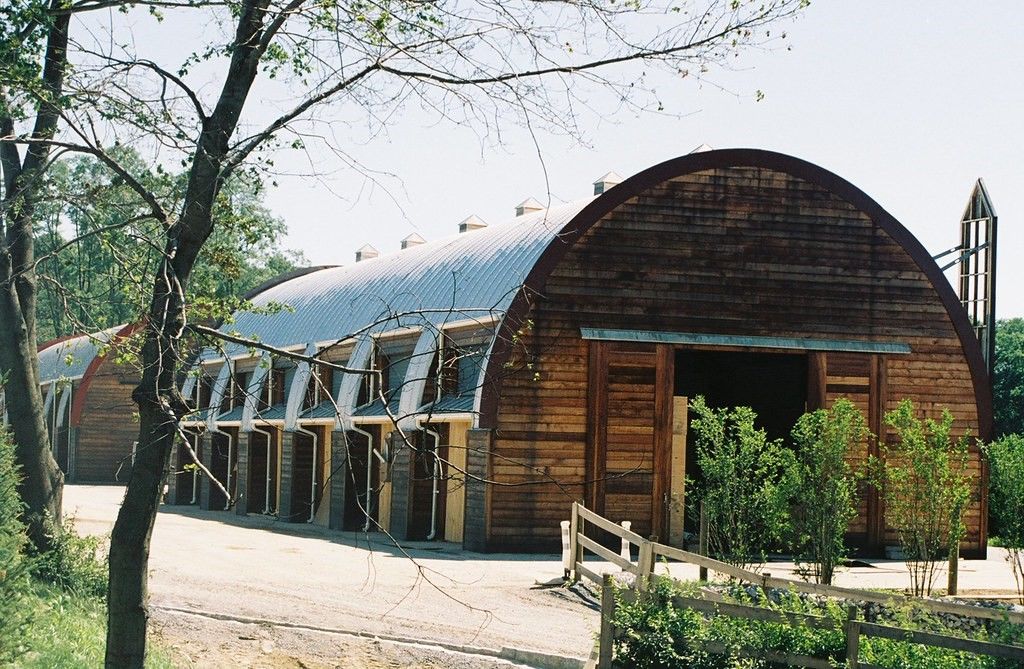

Corrugated Fiberglass Roofing

Any person would have the ability to conclude that the roof is one of the important parts of any structure, whether this might be a property building, a storage shed, a garage or an industrial establishment. In any provided structure, corrugated fiberglass roofing is an extremely suggested and cost reliable option to other roof product readily available in the market today.

In business facilities, setting up a brand brand-new corrugated fiberglass roofing is fairly simple and efficient and at very minimal cost. Any business owner would wish to begin their organization at the soonest possible time, or would prefer that their company operations will not be interrupted. Setting up a metal roof is one of the efficient methods to accomplish such goals.

Corrugated roofing products were first introduced to the market as sheet metal. These functions made it a popular roofing solution amongst commercial building owners for numerous years.

Fiberglass is water tight and really long lasting, and at the same time considerably lighter in weight. Another notable feature is its capability to offer higher rigidness as compared to a flat metal sheet with the same density and weight. In effect, this can produce a substantial decrease in the cost and weight of the set up roof.

It is however essential to bear in mind that in thinking about the setup of a corrugated fiberglass roof, you have to hire the best roofer. There are numerous roofer who have comprehensive experience in setting up roofing systems especially in installing metal or corrugated fiberglass roof. The majority of experienced veteran contractors have a lot of experience metal or fiberglass, and can conduct thorough routine check-ups on your roofings if needed.

In thinking of installing new roofing, or even roof repairs, be sure to make a background referral check on your professional. The agreement ought to reiterate the type of roofing material set up, the time frame, and anticipated date of completion and of course the agreed expense.

The fiberglass corrugated roofing system is one of the most intriguing materials among the corrugated roofing system installations. It is nevertheless important to keep in mind that in thinking about the setup of a corrugated fiberglass roof, you have to employ the best roofing contractor. There are many roof contractors who have comprehensive experience in setting up roofing systems specifically in setting up metal or corrugated fiberglass roof. In thinking of installing new roof, or even roof repair work, be sure to make a background referral check on your specialist.

Show Less

We at Stuart Roofer Services aim to produce the roof of your dreams! Call us today and set up a consultation with our specialist roofers. You won’t be dissatisfied. Call today for Roofing Services in Cleveland!

We can provide Roof Leak Repairs for all areas in Cleveland including: Cuyahoga County, Bedford Heights, Bedford Hts, Garfield Heights, Garfield Hts, Highland Hills, Highland Hls, North Randall, Warrensville Heights, Warrensvl Hts, Orange Village, Warrensville Hts and in Area Codes 440,216